Examples of plant layout and design

Hi, I’m Jack Greene. I sketched these layouts; most are real buildings which I have been in. Some I built, some I laid out or modified. Although none is perfect, the examples are full of sound principles, and represent actual, productive, operations. (Sound principles allow a smooth product flow; provide adequate space for equipment, people, processes, material, services and support, and inventory; utilize building space well; consider future technology and volume changes; accomplish the inevitable relocations with minimum interruption.)

They encompass a wide variety of facility characteristics, and of process characteristics. However, no example here is likely to fit your specific needs. None of these examples has buildings like yours or the same dimensions; the equipment and products and volumes won’t match. (There won’t be an answer elsewhere on the internet either, for your specific parameters.)

To discuss how to achieve a productive layout for Your specific challenges, circumstances, timing, and budget, call at no cost at 843-422-1298 or e-mail. Let’s talk; outline your situation and objectives. I’ll suggest ideas and options. Now, for the only commercial you will get: JPR can help when you need hands-on assistance with layout and facility planning; guidance or formal training, another pair of experienced hands and eyes or simply to talk out an issue.

By the way, layout can often be performed remotely, with internet, Zoom, cameras, phone. JPR has recently completed a sophisticated international project remotely.

This tends to be the most popular page on jacksonproductivity.. Thanks for your interest, and I hope you’ll see an example or spark an idea that leads to a workable layout for you.

Index of examples

A. Single story layout.

- 1. Straight line flow

- U shaped flow

- In a building designed for distribution, to adapt to another use

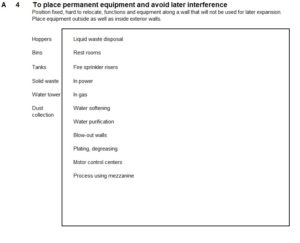

- To place permanent equipment and avoid later interference

- Distribution center

- Cellular flow

- Modular work flow

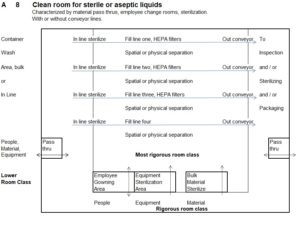

- Clean room for sterile or aseptic liquids

- Clean room for devices, semiconductors

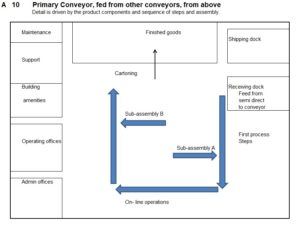

- Primary Conveyor, fed from other conveyors, from above

- One product, with several components, not conveyorized

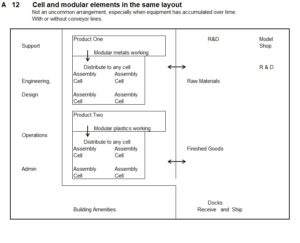

- Cell and modular elements in the same layout

- Electronics fab and test

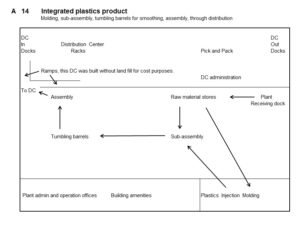

- Integrated plastics product

- From dedicated cells into modular packaging lines

- Model and prototype shops, pilot plant

B. Multi-story building

- Multi-story building, utilize vertical flow

- Multi-story building, two elevators

- Multi-story building, one elevator

- Multi-story building, services on another floor

C. Buildings set on plot plans

- Outside storage, liquid and dry bulk materials

- Outside storage, large components and product handling

- Constrained by adjoining property

- Unconstrained by adjoining property

- Details of dock characteristics